Ready to evolve your business?

Request a demo to see how we can help.

Request a demo to see how we can help.

Optimizing inventory visibility is crucial for businesses today. By utilizing modern inventory management software, businesses can aggregate data to provide a comprehensive view of inventory availability throughout the entire network. This enables them to minimize stock outs and order cancellations, meet service-level agreements, and enhance the customer fulfillment experience.

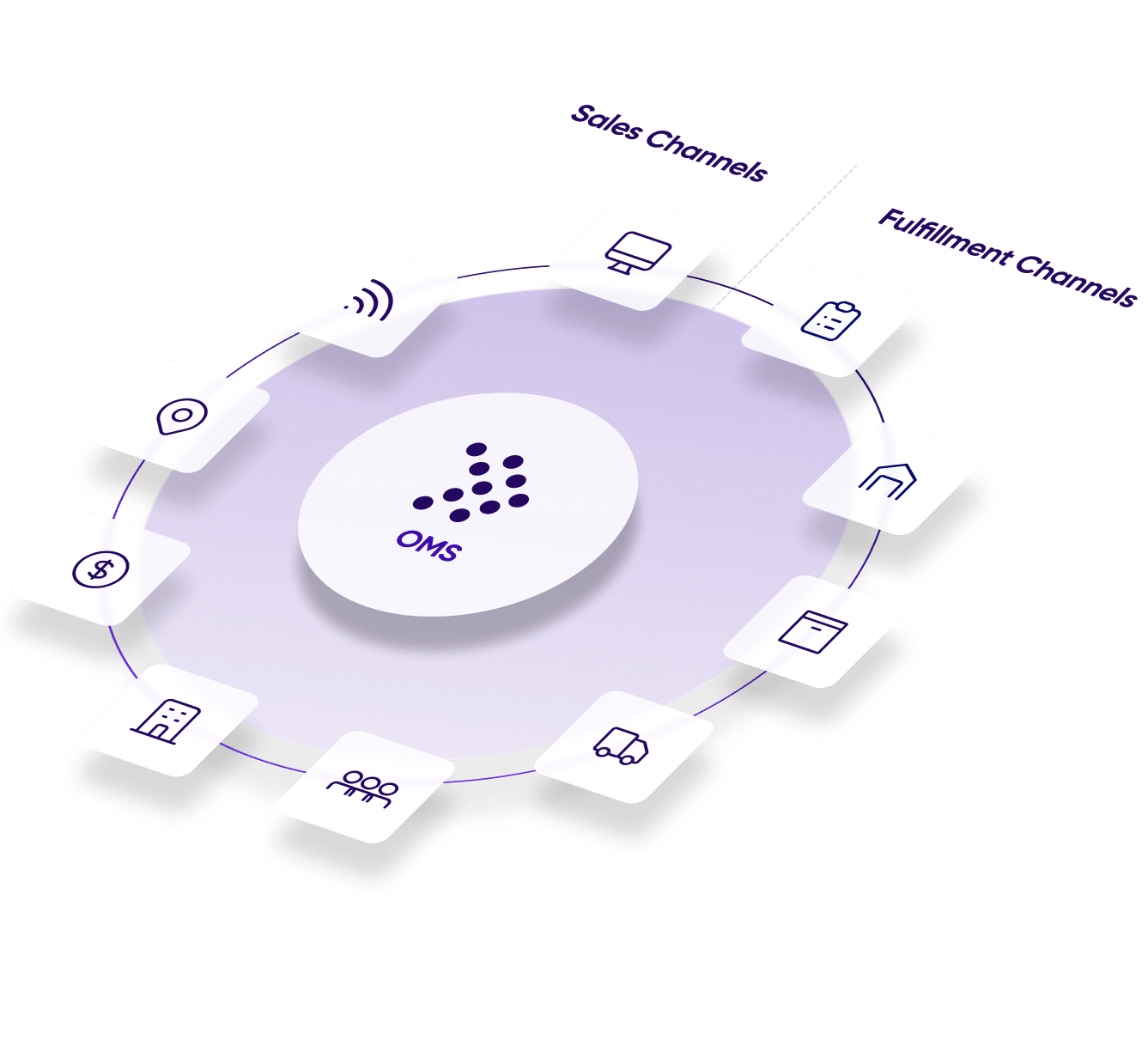

Real-time synchronization of inventory across sales channels and locations is a key functionality that businesses often lack. Without this capability, it becomes challenging to track inventory across a vast network and efficiently route products for fulfillment.

Syncing inventory offers more than just improved visibility. It enables businesses to manage buffer inventory levels, optimize available-to-promise (ATP) inventory, track inventory in transit, and analyze inventory positions by different channels or warehouses.

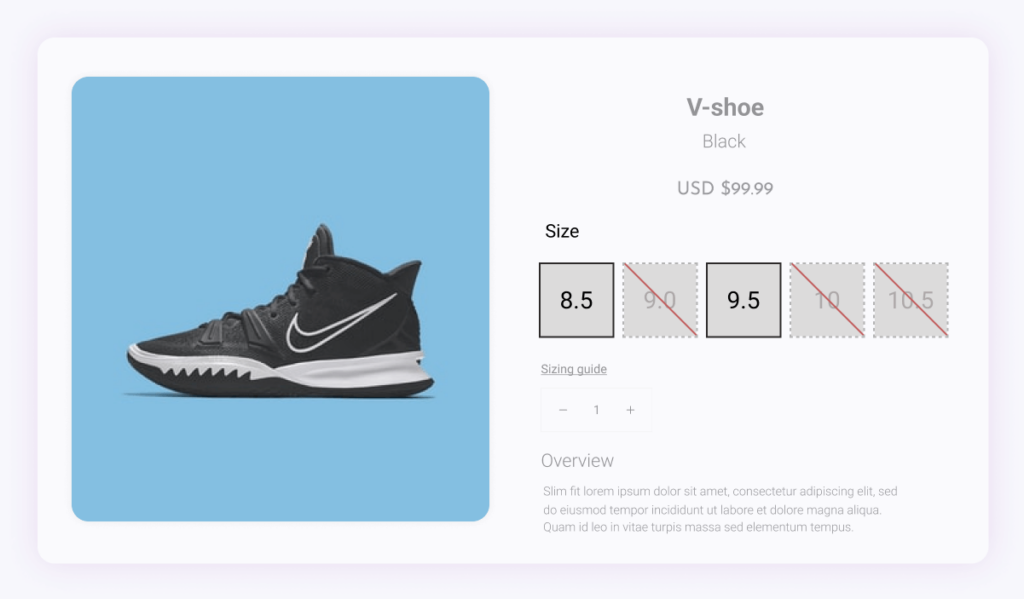

Accurate, real-time data empowers businesses to increase inventory turnover, reduce markdowns, and support various multi/omnichannel models such as buy-online-pickup-in-store (BOPIS), ship-to-store, and store fulfillment. Syncing inventory with e-commerce product detail pages (PDPs) also provides customers with precise information about available stock for purchase.

Businesses employ demand forecasting to analyze historical sales data, trends, and upcoming events, enabling informed decision-making for inventory planning and quick response to unforeseen circumstances. Demand forecasting is facilitated by ERP platforms or standalone software like Netstock, SAP Business Planning, and IBM Planning Analytics.

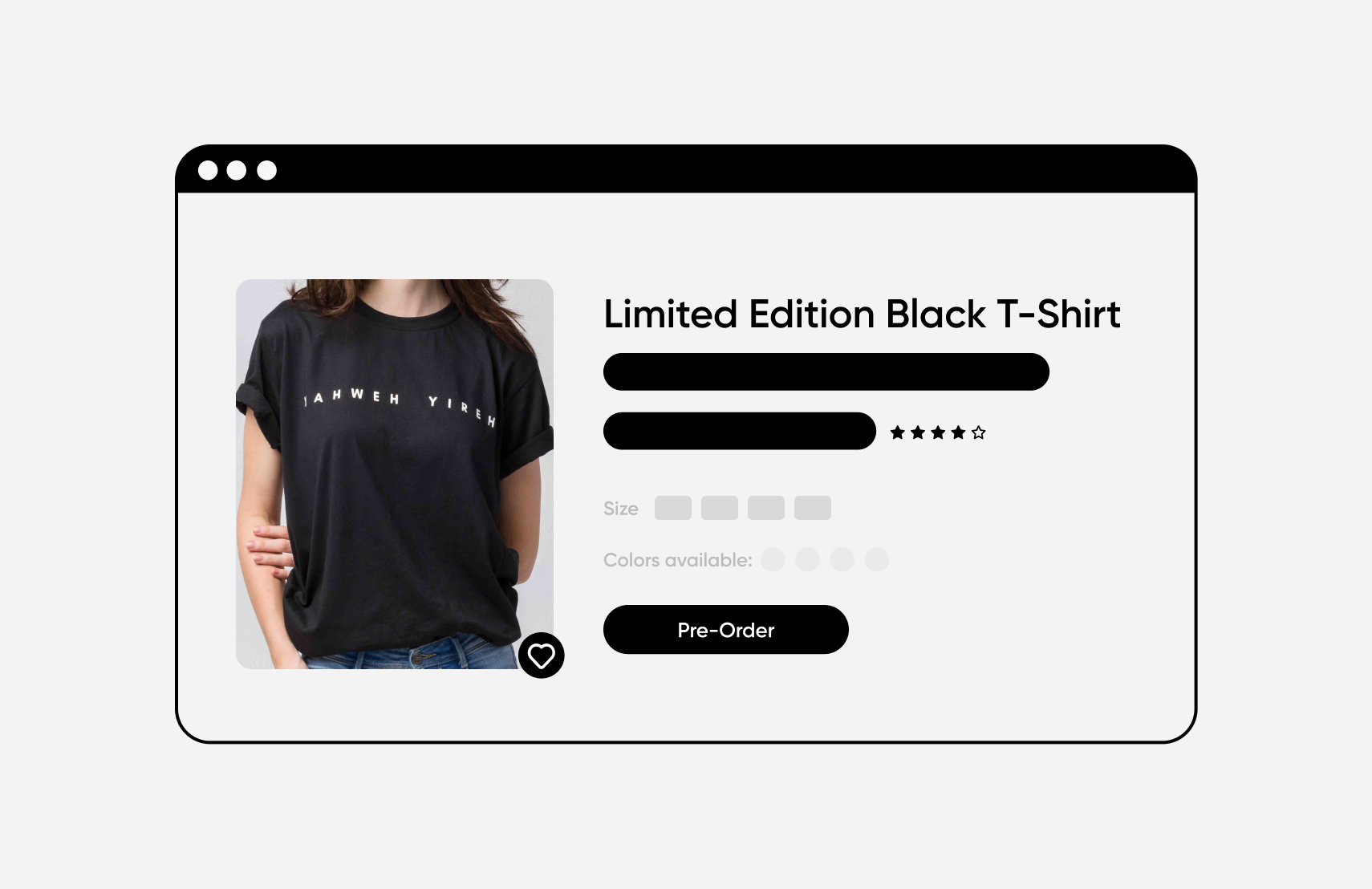

Modern OMS applications offer pre-order and backorder mechanisms to accurately assess inventory requirements and meet customer expectations. Pre-orders help build hype, gauge demand, and adjust inventory levels prior to product launches, reducing financial risks and generating anticipation. ATP inventory ensures availability for sale and anticipates future needs based on data-driven forecasts. With pre-order capabilities, companies can sell items before they are available and release them on specified pre-order release dates.

Backorders allow businesses to complete sales and retain customers while assessing inventory needs. Effective management of customer expectations is crucial. Communicating revised delivery dates promptly is key to maintaining positive customer relationships.

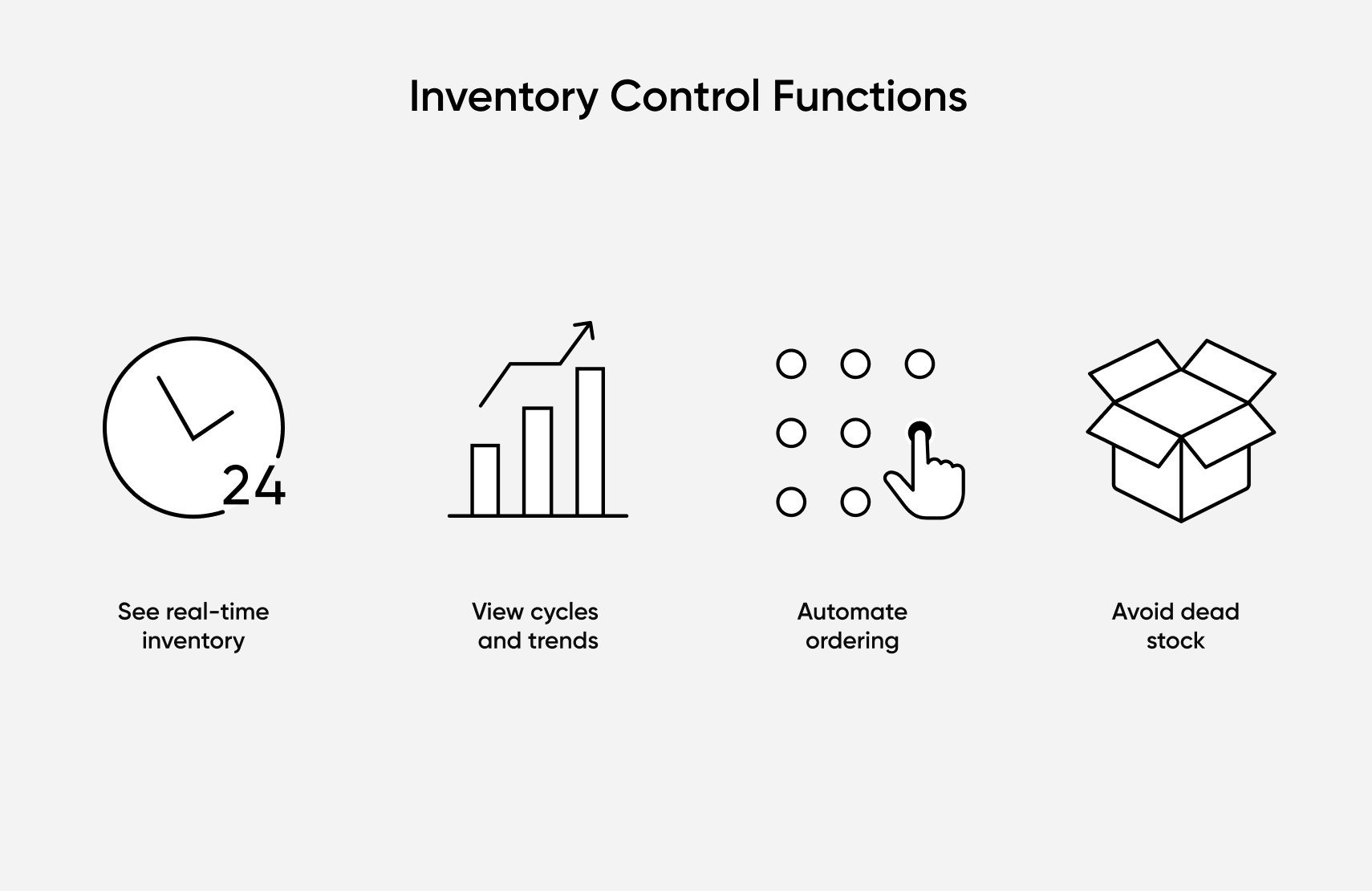

A subset of inventory management is inventory control, or stock control. Inventory control ensures the optimal amount of supplies within a business. It also seeks to maximize profit while minimizing the total cost of inventory but still provides customers with products in a timely and efficient way without sacrificing customer satisfaction.

Modern inventory management software is often equipped with inventory control systems, making it easier for retailers to optimize stock levels and extend the data model to fit business needs.

A well-functioning inventory control system should allow companies to categorize inventory by attributes, locate items, pool inventory, and control the availability of stock to sell in each channel, market, or region. It should also allow them to set accurate and specific reorder points to replenish stock when needed. Companies can use software to plan for sales and stock-outs and prevent the buildup of dead stock, also known as unsold inventory that sits in storage and is not expected to be sold in the near future.

01/03

Marketplace strategy and operations @ fabric. Previously at Modsy and FRONTGATE.

Marketplace strategy and operations @ fabric. Previously at Modsy and FRONTGATE.

Tech advocate and writer @ fabric.

Tech advocate and writer @ fabric.

Tech advocate and writer @ fabric.

Tech advocate and writer @ fabric.

Tech advocate and writer @ fabric.