PIM and PLM: Does Your Business Need Both?

Products are the lifeblood of brands and retailers. Companies exist because they have products to sell. Yet, bringing these products to market requires companies to keep track of many moving parts. Doing so without a standardized process leads to bottlenecks and inefficiencies.

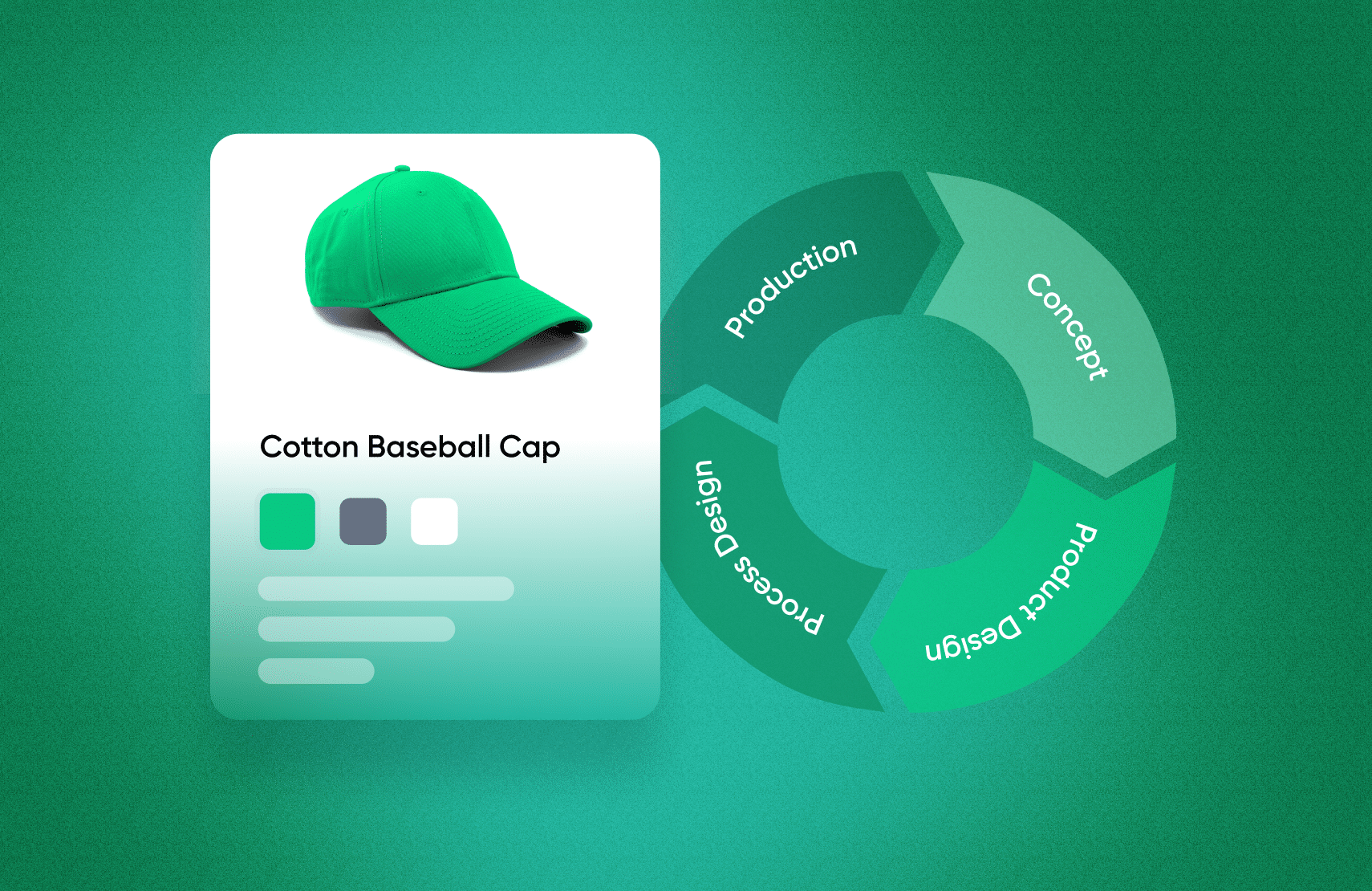

Product information management (PIM) and product lifecycle management (PLM) are two of the most useful product management software solutions that retailers use, but they’re often misunderstood. While they both play a role in successfully creating, marketing, and selling your products, there are some fundamental differences between the two.

What Is PIM?

PIM is the software-based process of gathering, storing, editing, and distributing product information. PIM software handles all types of product information, including:

- Titles

- Descriptions

- SKUs

- Taxonomies and categories

- Images

- Technical specs

- Channel specific information

PIM data is uploaded to the system from any number of external sources. Common examples include ERP systems, DAM systems, and spreadsheets. As information is uploaded, the PIM will validate the data to ensure it is free of errors.

Once the product information is in the PIM, different business users can enrich the product data so that products are optimized for each sales channel. An example of product enrichment would be adding more target keywords to the product title of an item to be listed on Amazon.

The product information is then spread to all relevant sales channels such as e-commerce websites, comparison shopping engines, and social media platforms.

The Benefits of PIM Software

With a single source of truth for product data, businesses can enjoy considerable benefits from using a PIM. These include:

- Improved data quality

- Consistent customer experience

- Reduced time to market

- Easy integration with external systems

- Reduced management costs and risks

- Faster and easier updates

- Easy scaling

- Visibility into ownership and greater transparency

- Easier multichannel selling

Without a PIM, product data is unstructured, scattered across different spreadsheets and databases. This forces businesses to find and transform the relevant data into a structure that matches the needs of each unique platform. PIM systems eliminate this problem.

A PIM makes it far easier to manage product information. It allows retailers to easily create, manage, and enrich a large volume and variety of SKUs across channels. Additionally, retailers can import, enhance, and organize product information, then distribute product data wherever their customers are. A PIM allows them to retake control of their product data and deliver exceptional shopping experiences with complete accuracy.

What Is PLM?

PLM involves the management of the entire lifecycle of a product. The typical product lifecycle has four phases:

- Development: An idea is generated, researched, and designed (e.g. a prototype is created).

- Growth: The product is manufactured, marketed, and distributed

- Maturity: The product reaches its peak; it’s widely available and other competitors enter the market

- Decline: The demand for the product decreases as it becomes obsolete or loses market share to competitors

PLM software provides a data store for all the information needed for the design and manufacturing of a product. This improves the efficiency of the design and production cycles by making essential product information available to different teams across the organization.

The software can integrate data with other business systems such as ERP systems and manufacturing execution systems (MES). This brings clarity to ownership during different stages of product development and reduced time to market.

Because PLM focuses on the development of the product, it does not manage customer-facing product information. The information managed by a PLM generally includes:

- Manufacturing drawings

- 3D models

- Bill of materials

- Prototype specifications

- Versions

- Revisions

The Importance of PLM Software

Several cross-functional teams are involved in the process of introducing a new product. There’s the design team, engineering team, manufacturing units, and suppliers for the parts to create the product. This whole ecosystem needs to be in sync.

Being in sync can be challenging as all these teams work on different aspects. They also tend to work in different geographic areas, which spreads resources across disparate systems.

As a result, many teams work in silos, introducing problems. As companies grow and the supply chain of the modern world becomes fully integrated, you need to have a platform and processes that connect all stakeholders.

PLM software provides a data store for all the information involved in designing and manufacturing a product. With a centralized system, critical information is readily available to different teams across the organization.

PLM software facilitates this process by integrating with other business systems such as ERP systems, product information management (PIM) systems, and CAD systems. The efficiency of the design and production cycles improves as the software brings together the siloed teams and processes.

Best Practices When Introducing PLM

Following these best practices when implementing PLM helps ensure your company achieves the best possible outcome:

Moderate constraints

PLM enables companies to innovate culture in a structured way. While PLM can standardize processes, it should not be too restrictive. Setting up too many fixed rules and constraints may break a company’s spirit. It’s important to find a balance between standardization and letting people work how they prefer.

Multiple integrations

Your PLM system must integrate with the best-in-breed solutions, not just ERP and CAD systems. For many designers, software tools are like a religion. They have their preferred tool, avoiding different ones. A fully integrated PLM solution lets designers use their tools while ensuring others are on the same page.

Data and analytics

To prove the value of implementing PLM, you must determine what KPIs best measure the success of your implementation. That requires you to assess the exact outcomes you aim to achieve with PLM. It could be (to name a few):

- Better control of inventory

- Better management of suppliers

- Reducing (re)work

- Reducing scrap or waste

With a better understanding of your objectives, you’ll know which metrics to focus on as you build your PLM strategy.

How PIM and PLM Can Work Together

PIM and PLM systems serve different purposes and can be used effectively together. Making design data available to marketing and sales teams through the PLM can give them a better understanding of how the product is made. As a result, they can market and sell the product more effectively. PLM data can also help customer service reps. With a detailed understanding of an item’s specifications, they can answer product-related questions with greater ease.

With the customer-facing information available through the PIM, developers can better understand customer preferences. They can then use this understanding in the development process to create products that better match the customer’s needs.

To learn more about how a PIM can integrate seamlessly with your current e-commerce ecosystem, check out our fabric PIM solution.

Senior Vice President @ fabric. Previously, Head of Technology @ State of RI and Head of Retail Unit @ TCS.